Introduction

An animal feed mill factory is a specialized facility designed to process raw ingredients into nutritionally balanced feed for livestock, poultry, and aquaculture. These plants are essential components of modern agriculture, ensuring that animals receive consistent and high-quality nutrition that promotes growth, health, and productivity.

The demand for Animal Feed Mill Plants has risen globally due to the expansion of intensive animal farming, rising meat and dairy consumption, and the need for efficient feed production systems. Understanding the operational structure, technology, and cost factors is crucial for farmers, feed producers, and investors.

History and Development

The development of animal feed mill plants can be traced back to the early 20th century when mechanized agriculture began replacing traditional feeding practices. Initially, livestock were fed with loose grains or mash, which often led to selective feeding and uneven nutrient intake.

With technological advancements, modern feed mill plants emerged, capable of producing pelleted, crumbled, or mash feed with consistent nutritional content. Innovations in motor technology, die design, and automation have enabled these plants to handle diverse raw materials efficiently. Manufacturers such as RICHI have contributed to modernizing feed production with scalable and durable equipment.

Core Components of an Animal Feed Mill Plant

A typical Animal Feed Mill Plant consists of several key sections:

Raw Material Storage and Handling

Silos, hoppers, and conveyors store and transport raw ingredients

Proper material handling ensures continuous production and minimizes contamination

Grinding and Pulverizing

Hammer mills or roller mills reduce particle size for uniform mixing

Essential for achieving optimal feed digestibility

Mixing and Conditioning

Mixers combine grains, protein meals, vitamins, and additives

Conditioners add moisture and heat to improve pellet quality

Pelletizing or Extrusion

Feed passes through a pellet mill or extruder to form pellets or crumbles

Flat die and ring die pellet mills are common, with suppliers like RICHI providing high-efficiency models

Cooling and Screening

Cooled pellets reduce moisture content, harden for storage, and prevent mold

Screens remove fines and ensure uniform size

Packaging and Storage

Automatic bagging systems facilitate distribution

Allows bulk or bagged feed for commercial or farm use

Types of Animal Feed Mill Plants

Small-Scale Plants

Capacity: 1–5 tons per hour

Suitable for local farms or cooperative feed production

Lower investment, minimal automation

Medium-Scale Plants

Capacity: 5–20 tons per hour

Semi-automated with integrated grinding, mixing, and pelletizing

Ideal for regional feed producers

Industrial-Scale Plants

Capacity: 20–50+ tons per hour

Fully automated, integrated systems

High investment but capable of continuous operation

Modular and scalable designs from manufacturers like RICHI enable easy expansion https://richipelletizer.com/animal-feed-processing-plant/

Raw Materials and Formulation

Animal feed mill plants can process a wide range of raw ingredients:

Cereal grains: corn, wheat, barley, sorghum

Protein meals: soybean meal, cottonseed meal, fish meal

Fibrous materials: rice bran, wheat bran, alfalfa meal

Additives: vitamins, minerals, amino acids, probiotics

Raw material selection affects pellet quality, feed efficiency, and overall plant productivity. The ability to handle diverse ingredients allows feed mills to utilize locally available resources and reduce production costs.

Factors Affecting Animal Feed Mill Plant Price

The Animal Feed Mill Plant price is influenced by multiple factors:

Production Capacity

Higher capacity plants require larger motors, reinforced structures, and precision components

Automation Level

Fully automated feeding, monitoring, and packaging systems increase initial cost but reduce labor and operational errors

Build Quality and Material Selection

Alloy steel dies, rollers, and robust frames improve durability and lifespan

Plant Layout and Infrastructure

Efficient material flow, facility design, and logistics integration affect total investment

Regional Market Factors

Import duties, shipping, and local labor costs influence the final price

Operating Costs and Maintenance

Beyond the initial plant price, operators must consider ongoing costs:

Electricity and energy consumption

Labor expenses

Routine maintenance and replacement of dies, rollers, and bearings

Handling and storage of raw materials

Proper maintenance ensures consistent feed quality, reduces downtime, and prolongs equipment life. Manufacturers such as RICHI Pellet Mill provide technical support to optimize plant operations and maintenance schedules.

Applications in Animal Farming

Animal feed mill plants are used across multiple sectors:

Livestock farms: cattle, sheep, goats

Poultry farms: broilers, layers, breeders

Aquaculture: fish and shrimp farms

Commercial feed mills: supplying bulk feed to regional or national markets

Pelletized feed improves nutrient absorption, reduces wastage, and supports higher productivity and profitability.

Environmental and Sustainability Considerations

Modern feed mill plants incorporate environmentally friendly practices:

Use of agricultural by-products reduces waste and supports circular economy practices

Energy-efficient motors and systems lower electricity consumption

Pelletized feed improves feed conversion ratios, reducing overall resource use

Dust control and emission systems comply with environmental standards

Sustainable practices contribute to long-term economic and environmental benefits for animal farming operations. Read Full Report

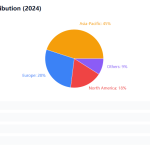

Global Market Trends

Rapid expansion of livestock and poultry industries drives demand for feed mill plants in Asia, Africa, and Latin America

Advances in automation, digital monitoring, and energy efficiency improve production consistency and profitability

Competition among global manufacturers, including RICHI, enhances quality and keeps prices accessible

Modular plant designs allow scalability for emerging markets and small-to-medium enterprises

Conclusion

An Animal Feed Mill Plant is a critical investment for modern livestock, poultry, and aquaculture operations. Factors affecting price include production capacity, automation level, material quality, plant layout, and regional market conditions. Evaluating long-term operational efficiency, maintenance needs, and sustainability ensures that feed producers achieve maximum productivity and profitability from their investment. Pellet machine price in philippines